We took up ZEB ahead of the industry and have accumulated a varied know-how of component technology.

We support activities for reducing CO2 emissions, the cause of global warming, to protect our global environment. We do this through systems that effectively use renewable energy and other technologies for reducing our environmental footprint and through development and adoption of energy-saving equipment and new technologies.

For a carbon-free society

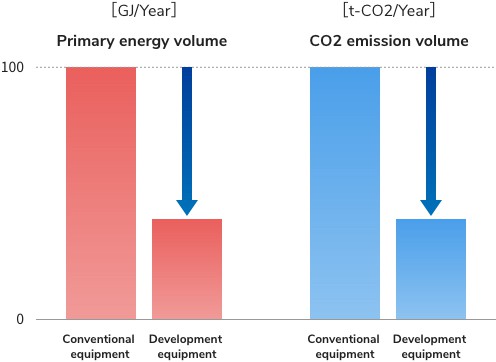

Supporting corporate activities for environmental friendliness by developing energy saving equipment

We contribute to saving energy and conserving the environment through the development of energy-saving equipment and by customizing optimum systems for customer facilities and supporting their operation.

Pursuing further evolution of Zero Energy Buildings through R&D of new technology

Renewable energy is natural energy and is therefore very unstable and always requires a backup. To this end, we are pursuing R&D in system control methods for optimum efficient use of renewable energy and use of clean energy such as hydrogen as a complementary technology to our ZEB technology.

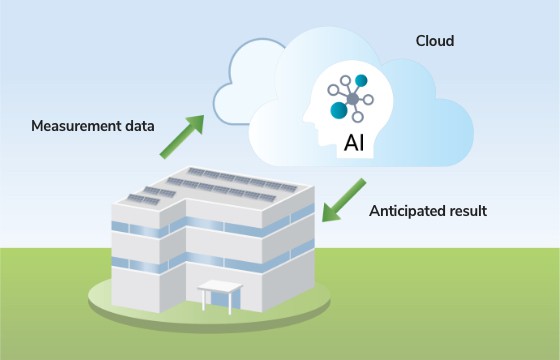

Optimum operation control through AI

Supporting environment conservation through ZEB development

As a ZEB planner, by proposing our renewable energy system, tried and tested in our facilities, we contribute not only to help conserving the environment but also lowering customer operating costs.

Sanken Sapporo Building

Overseas Cooperation of the SANKEN Energy Saving Technology

SANKEN is introducing and verifying ZEB’s elemental technologies overseas. The energy saving and comfort of our high-efficiency radiant air conditioning systems have been proven in Japan, but there are no demonstrations in South East Asia. SANKEN’s radiant air conditioning system has been adopted in the ZEB project spearheaded by BCA (Building and Construction Authority), a Singapore government agency as part of a major retrofitting project to their current Zero Energy Building, We are also jointly working with BEARS (Berkeley Education Alliance for Research in Singapore) to evaluate both the energy performance and thermal comfort acceptance for this system.

Protecting the environment together with the world

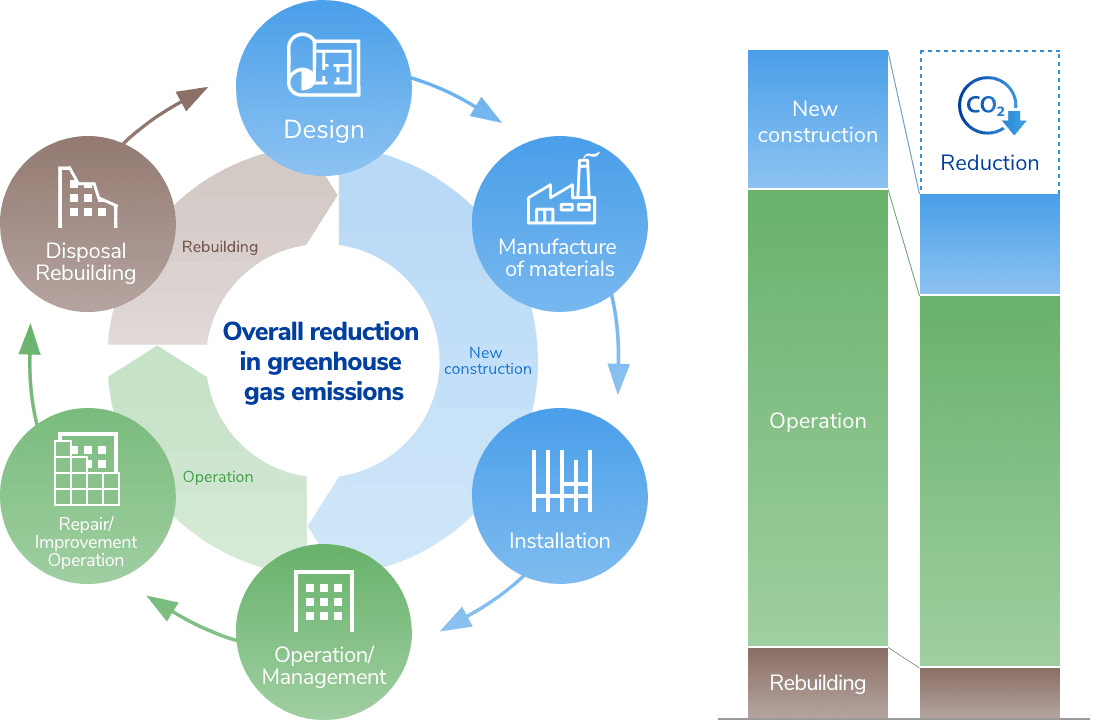

To contribute to meeting the GHG reduction target of the Paris Agreement, we are striving to reduce greenhouse gas emissions in the recycling of office materials, construction materials, reduce and process industrial waste and reduce greenhouse gas emissions in the life cycle of buildings.

Reducing greenhouse gas emissions during the life cycle of a building

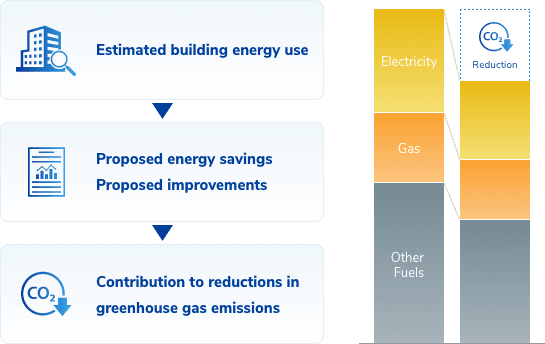

Promoting energy-saving activities together with our customers

Reducing the use of energy is essential in controlling greenhouse gas emissions. To this end, we are continuing in our efforts proposing activities to reduce CO2 emissions that are generated in the buildings of our customers.

Reducing greenhouse gas emissions resulting from building use

Combining digital technology for efficient construction

The creation of BIM models at the design stage enables swift consensus building and makes possible construction that eliminates rework. BIM data also improves field work substantially. 3D laser scanning is used to create extremely accurate drawings. This is another example of the digital technologies we use to pursue greater efficiency.

3D laser scan data

(point cloud data)

BIM data

Training engineers at subcontracting companies in quality and safety practices

We send instructors from our head office to our branches to hold training events for employers of our subcontractors. We teach the ABCs of safety and quality, such as how to avoid a recurrence of labor accidents and quality problems. The Sanken rules and other best practices are taught to instill proper safety management practices and to maintain and improve quality of construction.

Promoting life cycle management of buildings

Sanken Setsubi Kogyo handles all aspects of design and construction of pipe projects, electrical work and construction work.

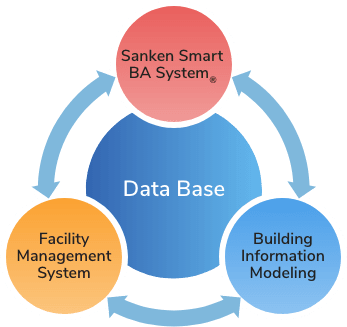

We also provide a central monitoring system called “Sanken Smart BA System®,” which integrates a remote monitoring function. Since it is an open system, a variety of software and hardware are freely combined to build an optimum system that takes function and cost into account. This system takes care of a variety of life cycle requirements that traditional central monitoring is unable to handle.